posted 57 months ago (Friday, August 16), edited 57 months ago by

jne4sl

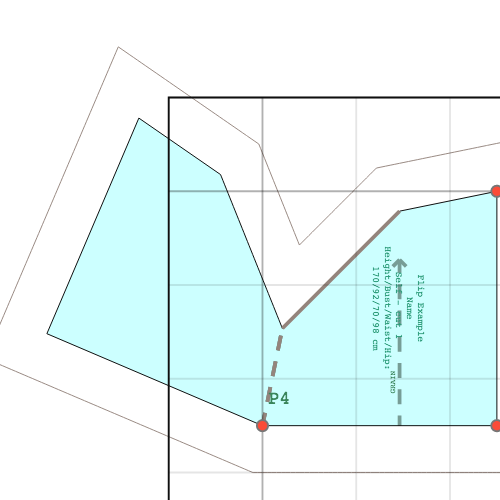

That doesn't fix the problem for the pattern I was working with. The trace is clockwise, and the first element is a neckline. If I add the first point of the neckline as the last point of the trace, nothing changes. If I add the fold line as the last element of the trace nothing changes. If I replace the neckline with a line [neck.p1:neck,p2], it works. If I replace the neckline with a new arc, neck_new = arc(neck.p1, neck.p2, neck.a1, neck.a2), it works. All I can figure is the particulars of the neckline are causing an error at the initial point of the path. Similar to sort of blips that might occur at any other intersection of the path, in particular maybe the sort of blip, that throws a point of the seam allowance inside the contour of the path. Anyway, just a guess. Maybe there's nothing *better* about the new arc, but it just happens to work with 'along' while the first one didn't. I've scratched my head over this behavior before, I just didn't spend any time trying to figure out if I was causing it.

Works fine with a fold, works fine with no flip or fold, but with a flip the seam allowances are wrong. If the path is replaced with a line (uncomment line 11), then flip works.

Something about the path created by along, is incompatible, with creating the seam allowance.